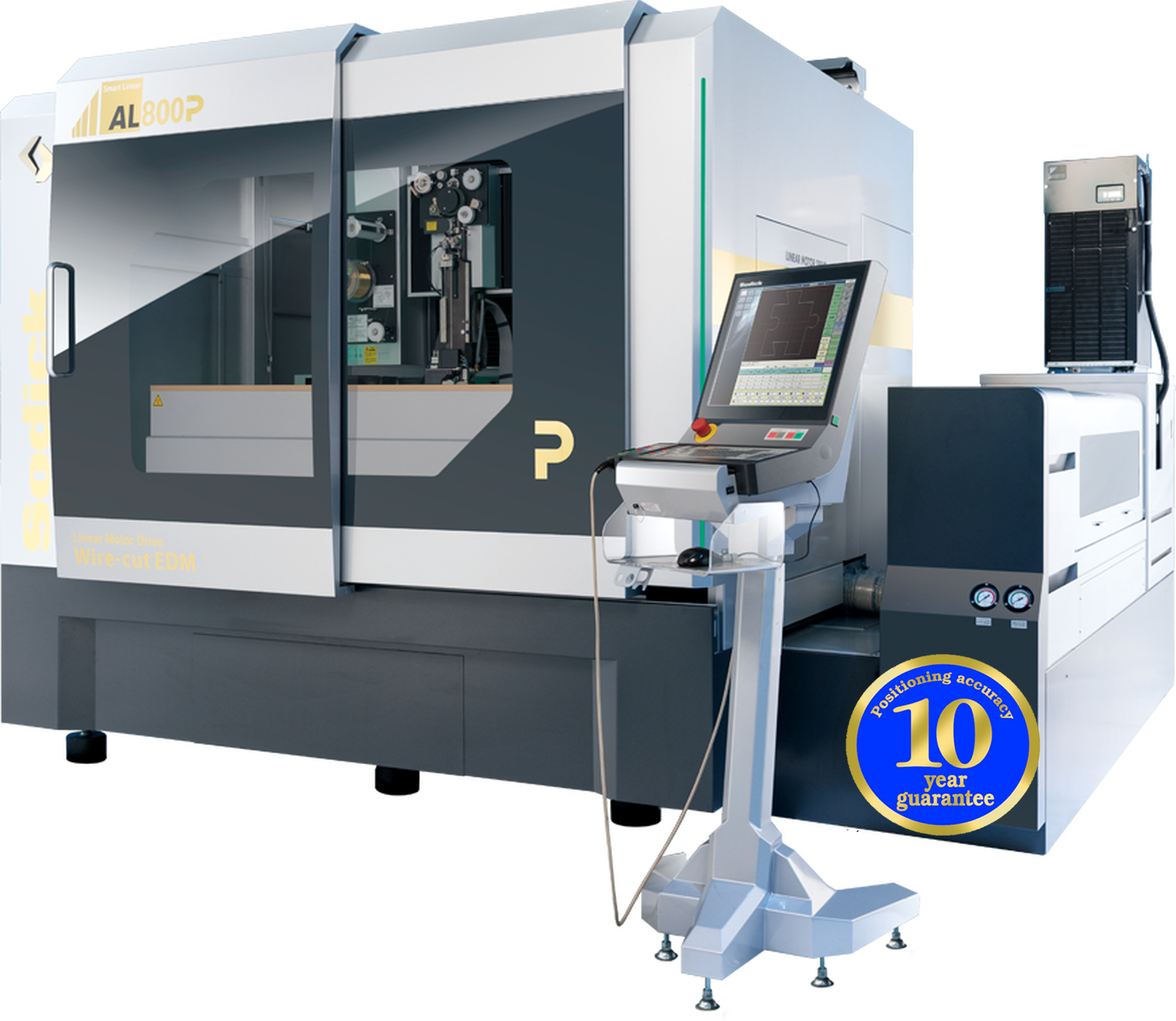

Description

The AL800P’s novel construction and system that minimizes thermal displacement, achieves higher-precision and faster machining of large Parts and molds. Our largest EDM in the ALP Series.

Features

- 10-Year Positioning Guarantee

- 4 Axis Linear Motor Drive System

- Digital-PIKA-W Plus

- Motion Controller

- Barrell-Free Effect Control II

- NC Device

- TMP Control II

- Windows Operating System

Specifications

| X - Axis Travel | 31.50" (800 mm) |

| Y - Axis Travel | 23.62" (600 mm) |

| Z - Axis Travel | 9.84" (250 mm) |

| Work Tank Inner Dimensions W x D | 55.51" x 43.70" (1410 x 1110 mm) |

| U, V - Axis Travel | 5.91" x 5.91" (150 x 150 mm) |

| Max. Taper Angle | ± 25° plate thickness: 5.12" (130 mm) |

| Max. Workpiece Dimensions (During flushing machining) W x D x H | 49.21" x 40.16" x 9.45" (1250 x 1020 x 240 mm) |

| Max. Weight of Workpiece (during flushing machining) | 3,307 lbs (1500 kg) |

| Wire Electrode Diameter | .002" ~.012" (0.05 ~ 0.30 mm) *1 |

| Wire Tension (N) | 3 ~ 23 |

| Max. Wire Feed Rate | 16.54 in/sec (420 mm/sec) |

| Distance from Floor Surface to Upper Surface of Table | 39.17" (995 mm) |

| Machine Tool Dimensions W x D x H | 129.92" x 143.70" x 95.08" (3300 x 3650 x 2415 mm) |

| Machine Installation Dimensions W x D | 180.31 x 198.82" (4580 x 5050 mm) |

| Total Unit Weight | 12,676 lbs (5750 kg) |

| Total Power Input | 3-phase, 50/60 Hz, 13 kVA |

4-Axis (XYUV) Linear Motor Drive

High-performance linear motors developed and manufactured by Sodick are adopted for the four XYUV axes. They can maintain accurate axis movement with no backlash semi-permanently, something that is impossible with conventional ball screw drive methods. The high response and high tracking performance that are features of linear motors achieve accurate position control and excellent discharge characteristics during machining.

High Rigidity Construction and Precision Thermal Compensation System

The AL800P adopts a high rigidity construction supported by the ultra-precise roller guide as well as featuring a machining fluid circulation system for major structural components. In addition, a newly developed high-precision thermal compensation system and automatic temperature control by a high-performance inverter cooler minimize the thermal displacement during high-precision machining of large work pieces.

Latest “SPW Power Supply” NC Unit and New Machining Circuits

A variety of the latest technologies for highspeed, high-precision, and high-quality machining, such as Digital-PIKA-W Plus, TMP control II, Barrel-free Effect Control II, new tension servo function, and automatic float control are installed as standard to achieve stable high-efficiency machining with the minimum number of cuts. The vertical 19-inch touch panel screen offers advanced operability and functionality.

10 Year Positioning Guarantee

At Sodick, we believe in our product. This is why we offer a 10-Year Positioning Accuracy Guarantee on our linear motor driven Wire and Sinker EDMs. We guarantee that you will not lose any accuracy within the linear motor drives. Learn more at 10 Year Guarantee

Thermal Commit (TH COM)

Through sensing, the temperature of each component of the machine is precisely corrected and the Thermal Commit (TH COM) function, which provides various diagnostic functions, minimizes thermal displacement due to temperature changes in the installation environment and during high-speed driving.