Description

The ALC600G iGE+, Rigid Linear Motor Driven CE Certified Wire EDM Machine, is one of the newest additions to the Sodick product line-up. This new machine includes some exciting new features, such as a full security enclosure, next-generation SPW control with Smart Pulse Generator, and other performance boosting technologies. The ALC series wire EDM offers the most advanced safety features on the market, in full compliance with international CE specifications.

Features

- 10-Year Positioning Guarantee

- Rigid Linear Motor Drives (X, Y, U, and V axes)

- Absolute Linear Scale (X, Y, U, and V)

- 2 Year Warranty Standard

- Full Security Enclosure

- CE Specification Compliant

- SPW (Smart Pulse Wire Control)

- Tablet Style Control Features

- 19″ LCD Touch Panel Screen

- Smart Pulse Generator

- Digital Pika-W Plus – Super Finishing Circuit

- Advanced Step Machining

- High Precision Positioning Sensor FT-II

- Ceramic Work-Zone

- FJ (Fixed Jet) High Speed AWT

- High Quality Design

- Rigid Cast Construction

- Stable Platform and Environment

- 3 Sided Rise/Fall Worktank

- Intelligent Q³vic EDW – Automatic Programming System

- K-SMC Motion Controller

- Three Part Filtration System

- Slide Plate Lubrication

- Advanced Corner Control

- Energy Saving Circuit

- Dielectric Cooling Unit

- Heart NC – CAD-CAM System (on-board)

- Ion-Exchange Unit

- Windows Operating System

- Automatic Wire Tension Servo Control System

- Automatic Voltage Regulator

- Four Sided Clamping Table

- Z-Axis Automatic Fluid Level Control

Options

- SPW-E Control – Up to 8 Axis Simultaneous Control – Required for Multi-Axis Simultaneous “Turn and Burn” Capability

- Jumbo Wire Feeder 110 lbs (50 kg)

- Integrated ‘Jumbo’ Wire Feeder 44 lbs (20 kg)

- L-Cut Wire Chopper – Processes Wire for Convenient Storage

- HTP Circuit – High Voltage Circuit that Improves Machining Efficiency when Cutting PCD and Similar Materials

- Taper Flex – Hardware and Software to enable the Machining of Precision Taper Angles (Up to 22 and 45 Degree Options Available, Contact Sodick for Details)

- SodickCare +2 or +4 Extended Warranty

- UPS (Uninterruptable Power Supply)

Specifications

| X - Axis Travel | 23.62" (600 mm) |

| Y - Axis Travel | 15.75” (400 mm) |

| Z - Axis Travel | 13.78” (350 mm) |

| U, V - Axis Travel | 5.91” x 5.91” (150 x 150 mm) |

| Wire Diameter Range (min ~ max) | 0.002” ~ 0.012” (0.05 ~ 0.30 mm) (With Available Options) |

| Work Tank Dimensions W x D | 41.34” x 27.95” (1,050 x 710 mm) |

| Max. Workpiece Weight | 2,204 lbs (1,000 kg) |

| Distance from Floor to Table Top | 39.17” (995 mm) |

| Machine Tool Dimensions W x D x H | 98.23” x 113.98” x 92.32” (2,495 x 3,500 x 2,345 mm) |

| Machine Weight | 10,141 lbs (4,600 kg) |

Rigid Linear Motor Drives

Sodick’s ALC600G iGE+ rigid linear motor driven, high precision Wire EDM machine features new user-friendly EDM technology which further enhances productivity and EDM precision. The machine’s rigid linear motor axes drives are coupled with glass scales on the X, Y, U, and V axes which ensure precision cutting and positioning accuracy. Sodick’s X, Y, U, and V linear motor drives have no backlash and are backed by Sodick’s 10-Year Positioning Accuracy Guarantee. Sodick currently manufactures and delivers only linear motor driven machines, proving the unrivaled reliability of Sodick’s own rigid linear motor technology. Sodick’s rigid linear motors have the optimum flat design. The machine castings support the linear motor to achieve ideal linear performance, the ultimate design for precision machining.

CNC Smart Control – SPW

The new Sodick Control SPW (Smart Pulse Wire) has many attractive features, from the use of the industry standard Windows 7 operating system, to an enhanced, 19 inch horizontal TFT multi-touch screen. The ALC control design streamlines the former tablet and classic control modes into a single work screen with easy-access functions. The streamlined design also improves control processing speed, for a highly responsive user experience. The new SPW control also incorporates fully fiber optic cabling for instantaneous data communication, greatly improving responsiveness.

The NC programs are supported with 2D and 3D graphics. Maintenance screens show the status of the machine and remote access is possible for maintenance and supervision.

Smart Pulse Generator

The Smart Pulse Generator reduces the number of cuts necessary to achieve the required accuracy and surface finish. This reduction in time translates directly into a financial advantage.

Intelligent Q³vic

Intelligent Q³vic EDW technology allows the importation of 3D CAD files and is standard with the ALC Series. This automatic programming system detects the profile of a workpiece that can be machined with Wire EDM and extracts the machining contour. Significant savings in programming hours are possible thanks to this advanced software.

Sodick Motion Controller

The Sodick Motion Controller (K-SMC), accurately controls the high-speed and precise linear motor drive movements through commands from the NC unit. The K-SMC was heavily researched and developed to bring about new technical innovations to electrical discharge machining. Developed in Silicon Valley, CA, the K-SMC accurately controls high-speeds, rapid acceleration and precise positioning.

Eco-Friendly

The ALC Series features energy-saving designs and technologies. Compared to conventional EDMs, the Sodick Wire EDM Machine Range can reduce average energy consumption by up to 60%.

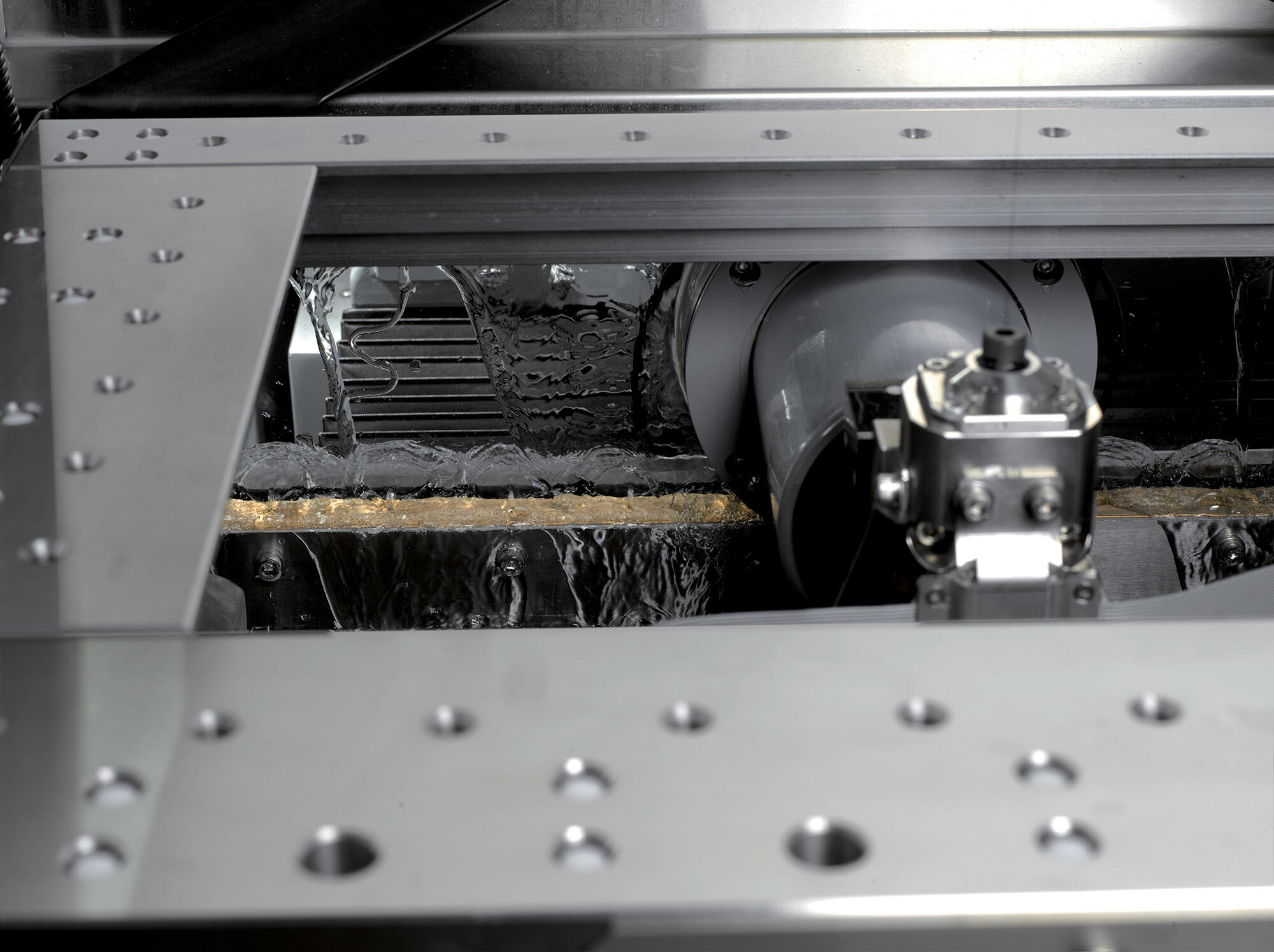

Fixed Jet High Speed Automatic Wire Threader

This AWT system allows submerged and non-submerged threading. Combining thermal wire cutting for a straighter wire and new water-jet function, the reliability of the Sodick AWT system has been further improved. The exclusive use of closed guides on the ALC600G iGE+ in combination with the FJ AWT further increases productivity.

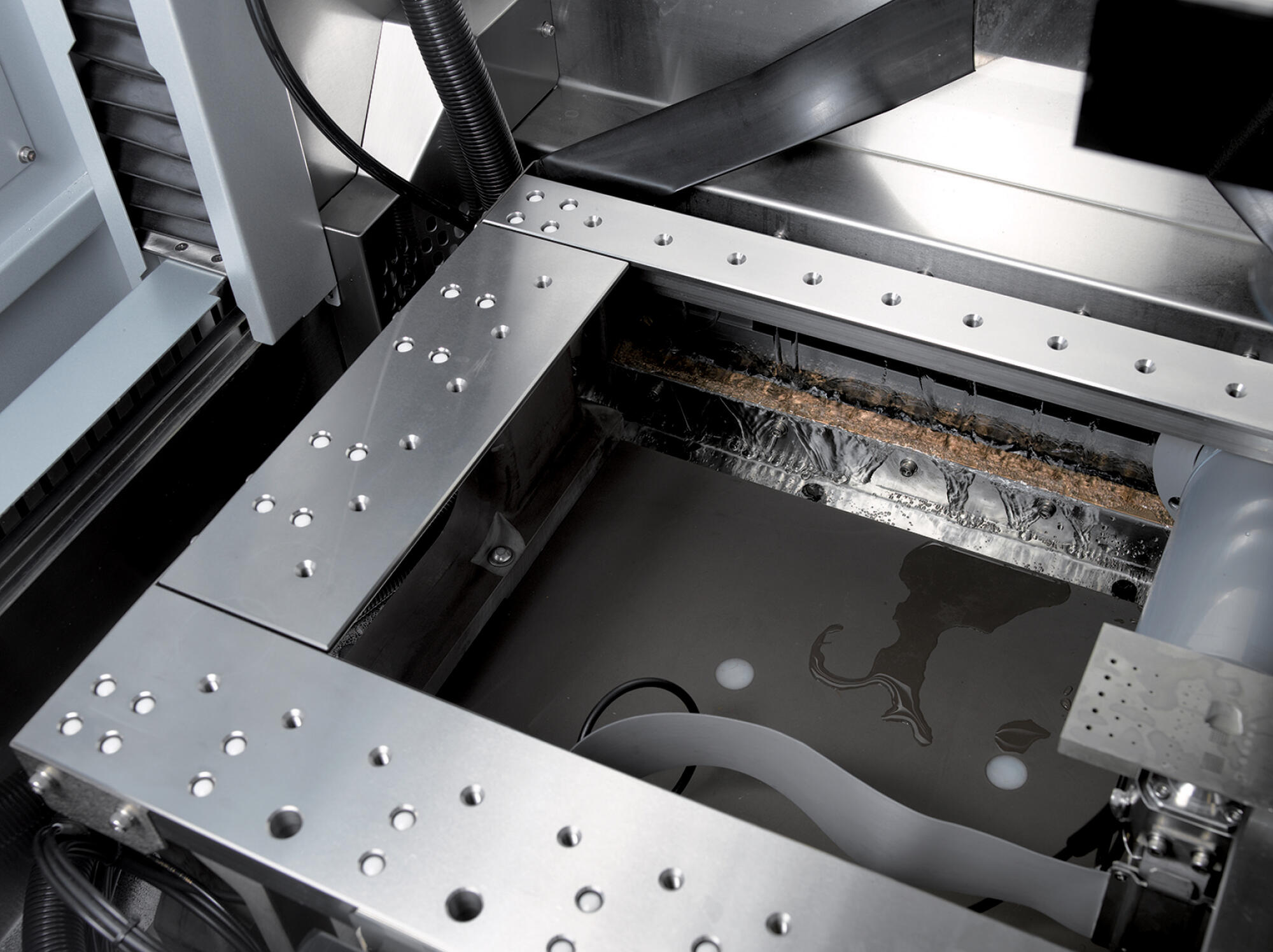

3-Sided Rise/Fall Worktank

The 3-sided rise/fall worktank ensures a large set-up space and ergonomic accessibility. Since 3 sides slide down, the machine requires less operating space. The no-drip feature ensures a clean shop floor, maintaining a safe work environment.

The fluid level is automatically adjusted according to the workpiece thickness and the operator can easily check machining progress even on thin workpieces because the slide tank can be stopped in intermediate positions while machining. The interior of the tank is made from stainless steel for quick maintenance (unpainted).

10 Year Accuracy Positioning Guarantee

At Sodick, we believe in our product. This is why we offer a 10-Year Positioning Accuracy Guarantee on our linear motor driven Wire and Sinker EDMs. We guarantee that you will not lose any accuracy within the linear motor drives. Learn more at www.sodick.com/our-company/10-year-positioning-guarantee

iGroove+ Technology

Our patented wire rotation technology, iGroove+, increases surface quality and accuracy while minimizing wire consumption by up to 39%.

Thermal Commit (TH COM)

Through sensing, the temperature of each component of the machine is precisely corrected and the Thermal Commit (TH COM) function, which provides various diagnostic functions, minimizes thermal displacement due to temperature changes in the installation environment and during high-speed driving.

Step-cut

It permits machining at the same speed as under standard conditions while significantly improving the accuracy and range of applications when machining shapes with rapidly changing material thickness, such as stepped shapes.

Sample

In cutting precision fitting parts with a 3.94″ (100 mm) thickness, Sodick has achieved the following: improved cutting speed, reduced cutting frequency, improved part accuracy and improved surface quality. A 32% cutting time reduction has been achieved using the ALC600G.

Material: SKD11

Thickness: 3.94” (100 mm)

Surface Roughness: 8 RMS (.20 µmRa)

Cutting Accuracy: +/- .00012″ (3 µm)

Wire Diameter: .008” (.2 mm)

Cutting Time: 2 hours 57 minutes

![Stepcut_sample_[sodick]2_40% Brad Schwind](https://sodick.com/wp-content/uploads/2022/09/Stepcut_sample_sodick2_40-Brad-Schwind.jpg)