Description

The AD35L Sinker EDM features Sodick’s Linear Motor Technology. Sodick’s expertise in EDM innovation using 3D design systems, the latest CAE technologies and numerous simulations have made it possible to create an improved basic machine structure with optimized rib arrangements; this increases rigidity by approximately 70%. With the new AD35L, machine deformation is minimized, allowing for optimum performance at high-speeds and rapid acceleration of the linear motors.

Features

- Linear Motor Drives (X, Y, Z Axes)

- 10 Year Positioning Accuracy Guarantee

- Dielectric Chiller

- SVC Circuit – Fine Finishing Circuit

- Energy Saving Circuit

- LAN

- Glass Scale Feedback

Options

- Various Chuck Options (call for details)

- Shuttle ATC (Automatic Tool Changer)

- C-Axis

Specifications

| X - Axis Travel | 13.78” (350 mm) |

| Y - Axis Travel | 9.84” (250 mm) |

| Z - Axis Travel | 10.63” (270 mm) |

| Work Table Size | 23.62” x 15.74” (600 x 400 mm) |

| Work Tank Size | 38.39” x 21.85” x 13.78” (975 x 555 x 350 mm) |

| Fluid Level (min ~ max) | 6.69” ~ 11.81” (170 ~ 300 mm) |

| Work Tank Capacity | 47.55 g (180 L) |

| Distance from Floor to Table Top | 31.89” (810 mm) |

| Machine Dimensions | 74.61” x 76.97” x 92.52” (1,895 x 1,955 x 2,350 mm) |

| Max. Workpiece Weight | 1,212 lbs (550 kg) |

| Machine Weight | 7,054 lbs (3,200 kg) |

Linear Motor Drive System & Small Footprint

Sodick’s linear motor drive system on the X, Y, and Z-Axes is the ideal mechanism that semi-permanently sustains high speed axes-movements and instantaneous response. There is no mechanical contact within the linear motor drive system, resulting in stable machining accuracy, reliability, and maintainability that can be sustained for years. The small footprint of the AD35L Sinker EDM is ideal for shops that are tight on space.

The New LN Controller and Power Supply Unit

The new LN controller will maximize the advantages of the linear motor drive system. “LN Assist” (standard) will enable even a beginner to operate the machine with ease. The power supply unit is designed to conserve energy.

Eco-Friendly

The AD Series features energy-saving designs and technologies. Compared to conventional EDMs, the Sodick Sinker EDM (Electrical Discharge Machine) Range can reduce average energy consumption by up to 60%.

SVC Circuit + No Arc Machining

The “SVC” Circuit is the Sodick standard in the process of achieving *Zero electrode wear and high-quality surface finish. To create a uniform satin surface, the “SVC” enables a no-polish finish for micro and non-forms that are difficult to polish, by producing high grade surface finishes equaling shorter processes, improved quality and prolonged stability.

The new electrical supply discharge circuit “Arc-less” enables no arc machining. It greatly reduces the machining time and number of electrodes used, leading to a dramatic reduction in cost and human errors.

*Zero electrode wear is an electrode wear rate of less than .06%.

New NC Unit with “TMM3” Discharge Power Supply

The AD35L features Sodick’s latest LN NC unit equipped with the new “TMM3” discharge power supply, capable of high-speed, high-precision and high-efficiency machining. It is equipped with LN Professional, automatic programming functions

10 Year Positioning Accuracy Guarantee

At Sodick, we believe in our product. This is why we offer a 10-Year Positioning Accuracy Guarantee on our linear motor driven Wire and Sinker EDMs. We guarantee that you will not lose any accuracy within the linear motor drives. Learn more at 10 Year Guarantee

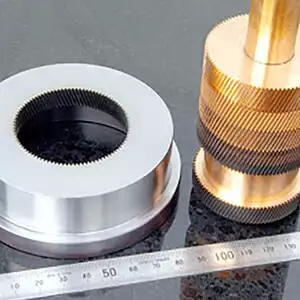

Samples

Material: Steel

Depth: 10 mm

Surface Roughness: 2.6 μm Rz

Machining Time: 17 hours 10 min

Electrode Material: Copper

Rotation: 20°