Description

The K1C is a high speed small hole driller that machines difficult to cut carbide and heat treated workpieces. Sodick’s patented Vitol machining fluid allows EDMing at much faster speeds than small hole machines that use water as a dielectric fluid.

Features

- Z – Axis Digital Control

- Standard TS Guide Set

Options

- External Dielectric Tank

- Riser Block Options (call for details)

- Amp Booster

Specifications

| X - Axis Travel | 7.87” (200 mm) |

| Y - Axis Travel | 11.81" (300 mm) |

| Z - Axis Travel | 11.81” (300 mm) |

| W - Axis Travel | 9.84” (250 mm) |

| Electrode Diameter | Φ.010” ~ .12” (Φ.25 ~ 3 mm) |

| Work Table Size | 9.84” x 13.78” (250 x 350 mm) |

| Distance From Guide to Table | 1.97” ~ 11.81” (50 ~ 300 mm) |

| Machine Dimensions | 31.89” x 34.25” x 79.33” (810 x 870 x 2,015 mm) |

| Max. Workpiece Weight | 220.5 lbs (100 kg) |

| Machine Weight | 1,212.5 lbs (550 kg) |

Latest Servo Technology

The Servo System dramatically improves responsiveness in servo detection. It offers 2 times faster machining speeds compared with previous models.

Micro-Step Servo

The K1C small hole drill is equipped with the Micro-Step Servo which maintains stable machining at all times.

Eco-Friendly

The K Series features energy-saving designs and technologies. Compared to conventional Hole Drillers, the K Series can reduce average energy consumption by up to 60%.

Ergonomically Friendly

The K1C is carefully designed to consider easy operation for operators. The operation panel is located at the front of the machine. The counter display is at the height of the operators view. The machine also comes with a tool tray for placing tools, dies and the like.

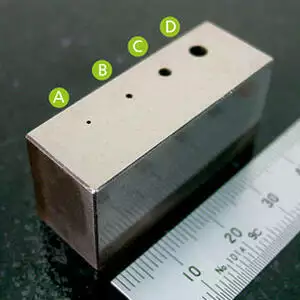

Sample

Material: WC

Thickness: .79” (20 mm)

Electrode Material: Copper (Cu) Pipe

Electrode Diameter / Time:

A: Φ 0.024” (Φ0.6 mm)

Time: 5 minutes

B: Φ 0.039” (Φ1.0 mm) Time: 6 minutesC: Φ 0.079” (Φ2.0 mm)Time: 7 minutesD: Φ 0.118” (Φ3.0 mm)Time: 6 minutes